Infection prevention is not just about choosing the right product, it’s about understanding the European Norms (EN standards) that define what “effective” really means. These internationally recognised benchmarks ensure that disinfectant solutions meet strict, proven criteria for performance, safety and reliability.

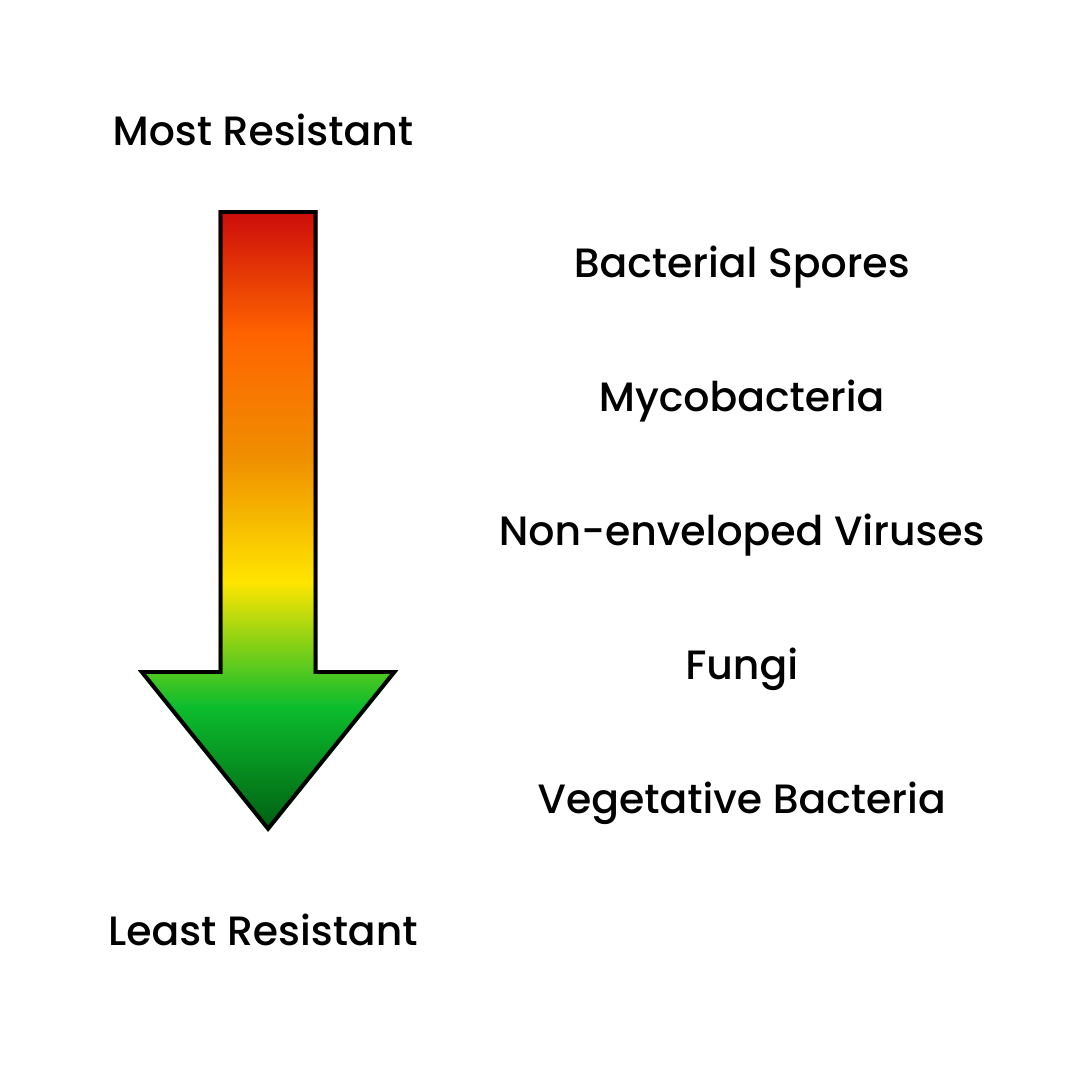

Why Microbial Resistance Matters

Microorganisms vary in how resistant they are to disinfection. For example, enveloped viruses like SARS-CoV-2 are relatively easy to kill. Bacterial spores, on the other hand, are extremely tough.

Here’s a simplified microbial hierarchy of resistance to disinfectants:

However, resistance alone does not determine the required level of disinfection.

The clinical context, including the device’s intended use, the risk of infection, and the type of tissue it contacts, is equally important.

For instance:

- A vaginal probe, which contacts mucous membranes and poses a high risk of infection, requires high-level disinfection.

- A hospital bed rail, which contacts intact skin and carries lower risk, may only require low-level to intermediate-level disinfection.

This resistance spectrum helps guide disinfectant formulation and testing.

What Are European Norms (ENs)?

To ensure disinfectants are effective in these varied contexts, they must meet minimum efficacy standards defined by European Norms (ENs).

These norms are standardised laboratory test methods used across European and international markets to measure how well disinfectants perform against specific microorganisms, such as bacteria, viruses, fungi, mycobacteria, and bacterial spores.

At Tristel, we align our products with these norms to ensure they meet the demands of real-world clinical practice. Here’s what you need to know.

ENs in Practice

EN’s provide standardised testing that balances chemistry, clinical context, and application method. They assess a disinfectant’s ability to kill bacteria, viruses, fungi, mycobacteria, and spores under controlled conditions that simulate real-world use—on surfaces, instruments or skin.

They consider:

- Where the disinfectant is used

(e.g., medical/healthcare sector, food sector, industrial/pharmaceutical, domestic industries) - What type of disinfectant is being used

(e.g., for surfaces, instruments, skin, air) - How it is applied

(e.g., immersion, spray, flooding, wipe/mop, fogging) - Which microorganisms are tested to support the various biocidal efficacy claims, based on clinical relevance and representativeness.

- Additional requirements for disinfectants used in patient-facing areas (e.g., safety for contact with staff, patients and visitors)

This layered approach ensures disinfectants are not only chemically powerful but also fit for purpose.

All disinfectants placed on the market must meet minimum efficacy requirements, typically including bactericidal and yeasticidal activity.

Here’s a simplified example showing how EN’s are selected based on how the disinfectant is applied in the medical sector:

EN’s Define Acceptance Criteria

Each EN not only specifies the microorganisms to be tested but also sets quantitative acceptance criteria for efficacy. In the medical sector, the standard requirement is:

- ≥5 log reduction for vegetative bacteria

- ≥4 log reduction for bacterial spores, viruses, mycobacteria, fungi, and yeasts

These thresholds ensure that products meet a consistent and clinically relevant level of performance before they can be marketed or used in healthcare environments.

Disinfection Levels: A Quick Guide

The CDC defines three levels of disinfection:

- Low-Level: Kills vegetative bacteria and enveloped viruses

- Intermediate-Level: Kills mycobacteria, fungi and non-enveloped viruses

- High-Level: Kills spores under controlled conditions

EN norms help validate these claims. For example, EN 17126 and when applicable, EN 17846 confirm sporicidal activity. EN 14476 and when applicable, EN 17111 or EN 16777 confirm virucidal activity. When a product passes these tests, you know it works.

Why It Matters

EN norms are more than numbers. They’re the foundation of good practice. They give healthcare professionals confidence that the disinfectant they’re using will do the job it claims to do.

At Tristel, we don’t just meet these standards. We build our products around them. Because when it comes to infection prevention, there’s no room for compromise.

Meet our Medical Device Disinfectants

Meet our Surfaces Disinfectants

No products found.