Manual disinfection is a proven and effective method for disinfection. One important factor influencing its success is the pressure applied during the wiping process.

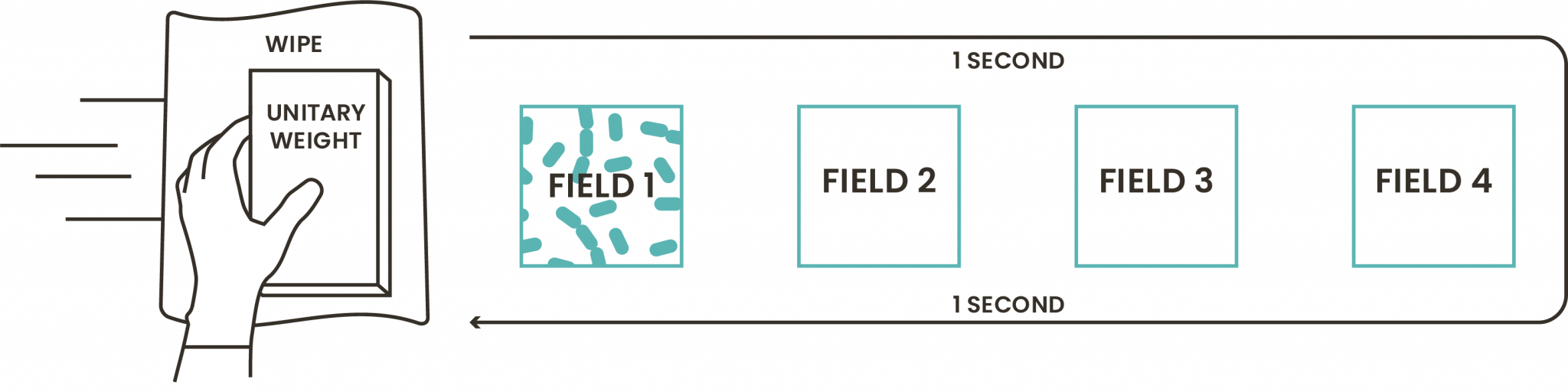

EN 16615 is designed to evaluate the performance of disinfectants when applied with a wipe. In this test, the disinfectant is added to a wipe, which is then wrapped around a standardised weight and moved across four test fields. The first of these fields is innoculated with microorganisms and an interfering substance.

After wiping, the microbial load on the first field is measured to assess both the disinfectant’s efficacy and on the other three fields whether microorganisms have been spread across the surface rather than eliminated.

The standardised weight used in EN 16615 ranges from 2.3 to 2.5 kg. But does this range truly reflect the pressure applied in real-world use?

To answer this, Tristel developed a bespoke test method that adapted the standard 4-field approach by introducing a range of weights. Tristel DUO ULT was tested under conditions both above and below the standard weight range to simulate the variability in wiping pressure. The results demonstrated that Tristel Duo ULT remains effective across a range of applied forces, reinforcing the reliability of manual disinfection when performed correctly.

The Background

EN 16615 outlines strict parameters to ensure consistent testing. It uses a unitary weight of 2.3 to 2.5 kg to simulate average wiping pressure, applied via a block with defined size and material. The test surface is PVC with a PUR coating, divided into four 5 x 5 cm fields. A standard blue Tork wipe is used unless the disinfectant is pre-impregnated, in which case only the tested wipe is approved for use.

While EN 16615 sets strict parameters for consistency, it doesn’t reflect real-world variability. The fixed weight of 2.3 to 2.5 kg may not represent typical user-applied pressure.

These limitations raise an important question: how does pressure variation affect efficacy?

To explore this, we set out to understand the impact of variable wiping pressure on disinfectant performance, aiming to bridge the gap between controlled testing and everyday use.

The Preliminary Test

At Tristel HQ, we conducted a blind study with 30 participants, each asked to wipe a calibrated scale with a Tristel DUO WIPE for 5 seconds. The highest and lowest pressures were recorded, and an average was calculated. Results ranged from 0.2 to 3.2 kg, with one outlier at 5.2 kg. The overall average was 1.6 kg, significantly lower than the EN 16615 standard of 2.3 to 2.5 kg. This confirmed our hypothesis: wiping pressure varies widely between users, highlighting a key limitation in the current validation method.

The Bespoke Test

To assess the impact of pressure on disinfectant efficacy, we developed a custom test based on EN 16615, using Staphylococcus aureus as the challenge organism. The goal was to explore any relationship between pressure and performance, not to revalidate efficacy.

We introduced six weight levels from 1 to 3.5 kg, reflecting real-world wiping pressures. A custom quartz-based object was designed to match EN 16615 specifications while allowing for adjustable, evenly distributed weight. Each configuration was tested in duplicate under consistent conditions, enabling a controlled evaluation of pressure variation.

The Results

All weight levels tested, except one, achieved complete elimination of microorganisms, with minimal spread to test fields 2 to 4. This indicates effective elimination without transfer across the surface.

Given the natural variability in microbiological testing, especially with the precision required by EN 16615, we ran each test in duplicate to identify any outliers. One failed result occurred at 2.5 kg in the first run, but no organisms were transferred to other fields, suggesting a localised anomaly. The second run at the same weight showed a complete kill, under identical conditions.

Interestingly, 2.5 kg aligns with the EN 16615 standard weight range, a test Tristel DUO has passed consistently. This isolated failure only reinforces the significance of the consistent pass results across all other weights.

In Conclusion

The data from our study does not reveal a trend between wiping pressure and disinfectant efficacy. Instead, it shows that Tristel DUO consistently achieved high log reductions across all pressure levels tested. This confirms that variable wiping pressure, known to occur in practice, does not impact the performance of chlorine dioxide.

These findings add to the robust body of evidence supporting Tristel DUO, which includes multiple EN 16615 tests across various organisms, simulated use studies with different users, and other EN methods that do not involve mechanical action. Together, they reinforce the reliability and effectiveness of our solution in real-world conditions.